1. Cov kev cai rau kev them cov pawg

Raws li txoj kev them nqi,cov chaw them hluav taws xob evmuab faib ua peb hom: AC charging piles,DC charging piles, thiab AC thiab DC kev them hluav taws xob sib xyaw ua ke.DC them chaw nres tshebfeem ntau yog ntsia rau ntawm txoj kev loj, chaw them nqi thiab lwm qhov chaw;Chaw them hluav taws xob ACfeem ntau yog ntsia rau hauv thaj chaw nyob, chaw nres tsheb, chaw nres tsheb ntawm txoj kev, thaj chaw pabcuam kev loj thiab lwm qhov chaw. Raws li qhov yuav tsum tau ua ntawm State Grid Q/GDW 485-2010 tus qauv,lub tsheb fais fab them nqilub cev yuav tsum ua tau raws li cov xwm txheej hauv qab no.

Tej yam kev mob ib puag ncig:

(1) Qhov kub thiab txias ua haujlwm: -20 ° C ~ + 50 ° C;

(2) Cov av noo sib piv: 5% ~ 95%;

(3) Qhov siab: ≤2000m;

(4) Lub peev xwm tiv taus av qeeg: qhov kev nrawm ntawm kab rov tav ntawm av yog 0.3g, qhov kev nrawm ntawm ntsug ntawm av yog 0.15g, thiab cov khoom siv yuav tsum muaj peev xwm tiv taus peb lub nthwv dej sine ua haujlwm tib lub sijhawm, thiab qhov kev nyab xeeb yuav tsum ntau dua 1.67.

Cov kev cai tiv thaiv ib puag ncig:

(1) Qib kev tiv thaiv ntawmlub tshuab them hluav taws xobLub plhaub yuav tsum ncav cuag: sab hauv tsev IP32; IP54 sab nraum zoov, thiab nruab nrog cov khoom siv tiv thaiv nag thiab hnub tsim nyog.

(2) Peb yam uas yuav tsum tau ua kom tiv thaiv (tsis pub dej noo, tsis pub pwm, thiab tsis pub ntsev tsuag): kev tiv thaiv ntawm lub rooj tsavxwm luam tawm, cov khoom sib txuas thiab lwm yam hauv lub charger yuav tsum tau kho nrog kev tiv thaiv tsis pub dej noo, tsis pub pwm, thiab tiv thaiv ntsev tsuag, kom lub charger tuaj yeem ua haujlwm tau zoo hauv qhov chaw noo noo thiab muaj ntsev.

(3) Kev tiv thaiv xeb (tiv thaiv kev oxidation): Lub plhaub hlau ntawmchaw them hluav taws xobthiab cov hlau bracket thiab cov khoom uas raug nthuav tawm yuav tsum siv ob txheej tiv thaiv xeb, thiab lub plhaub hlau uas tsis yog ferrous kuj yuav tsum muaj cov yeeb yaj kiab tiv thaiv oxidation lossis kev kho mob tiv thaiv oxidation.

(4) Lub plhaub ntawm lubev them nqi pawgyuav tsum muaj peev xwm tiv taus qhov kev sim zog cuam tshuam uas tau teev tseg hauv 8.2.10 hauv GB 7251.3-2005.

2. Cov yam ntxwv ntawm cov qauv ntawm cov hlau them lub plhaub

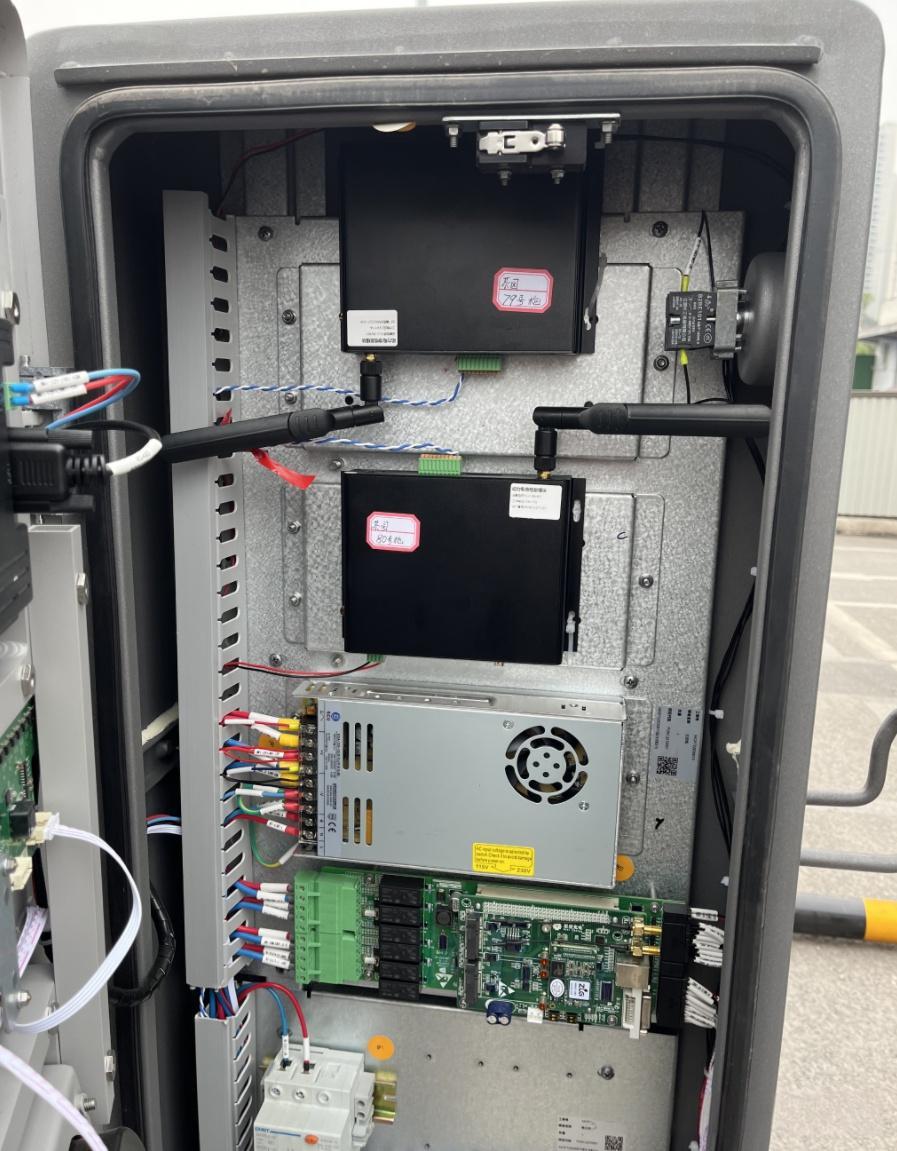

Lubpawg them nqifeem ntau yog tsim los ntawm lub cev them nqi, iblub qhov (socket) them fais, ib lub cuab yeej tswj kev tiv thaiv, ib lub cuab yeej ntsuas, ib lub cuab yeej siv daim npav, thiab ib qho kev sib cuam tshuam ntawm tib neeg thiab lub khoos phis tawj, raws li pom hauv daim duab hauv qab no.

Daim ntawvcov qauv hlau them nqi pawgyog ua los ntawm cov hlau carbon tsawg nrog lub thickness ntawm li 1.5 hli, thiab cov txheej txheem ua tiav siv cov hlau ntauwd punching, bending, thiab vuam cov txheej txheem. Qee hom charging piles yog tsim nrog ob txheej qauv hauv kev xav txog qhov xav tau ntawm kev tiv thaiv sab nraum zoov thiab kev rwb thaiv tsev kub. Lub duab ntawm cov khoom feem ntau yog rectangular, lub thav duab yog welded tag nrho, txhawm rau kom ntseeg tau tias qhov zoo nkauj ntawm qhov tsos, qhov chaw puag ncig yog ntxiv hauv zos, thiab txhawm rau kom ntseeg tau tias lub zog tag nrho ntawmcov chaw them fais fab tsheb, nws feem ntau yog welded nrog stiffeners lossis reinforcing phaj.

Feem ntau, sab nraud ntawm lub pawg yog teeb tsa nrog cov cim qhia vaj huam sib luag, cov nyees khawm vaj huam sib luag,kev them nyiaj interfacesthiab cov qhov cua sov tawm, thiab lwm yam, lub qhov rooj tom qab lossis sab yog nruab nrog lub xauv tiv thaiv kev tub sab, thiab lub pawg tau kho rau ntawm lub hauv paus teeb tsa los ntawm cov ntsia hlau.

Cov khoom siv txuas feem ntau yog ua los ntawm electro-galvanized lossis stainless hlau. Yuav kom ntseeg tau tiaschaw them fais fab tshebLub cev muaj qee qhov kev tiv thaiv corrosion, feem ntau cov khoom them hluav taws xob feem ntau yog txau nrog cov hmoov txheej sab nraum zoov lossis xim sab nraum zoov tag nrho kom ntseeg tau tias nws lub neej ua haujlwm.

3. Kev tsim cov qauv hlau los tiv thaiv xebpawg them nqi

(1) Cov tsos ntawm cov qauv pawg ntawm lub pawg them yuav tsum tsis txhob tsim nrog cov ces kaum ntse.

(2) Nws raug pom zoo kom lub hau sab saum toj ntawmev them nqi pawgmuaj qhov nqes ntau dua 5° kom tiv thaiv dej sib sau ua ke rau saum.

(3) Lub tshuab ziab khaub ncaws siv rau kev ziab khaub ncaws ntawm cov khoom kaw kom tiv thaiv kev sib sau ua ke. Rau cov khoom uas muaj qhov xav tau cua sov thiab qhib qhov cua sov, lub tshuab tswj cua sov + lub cua sov yuav tsum siv rau kev ziab khaub ncaws kom tiv thaiv kev sib sau ua ke.

(4) Tom qab vuam hlau ntawv, qhov chaw sab nraum zoov raug txiav txim siab tag nrho, thiab qhov vuam sab nraud raug vuam tag nrho kom ntseeg tau tias cov khoom ua tau raws liIP54 tsis muaj dejcov cai.

(5) Rau cov qauv vuam uas kaw xws li cov qhov rooj vaj huam sib luag stiffeners, kev txau tsis tuaj yeem nkag mus rau sab hauv ntawm cov qauv sealing, thiab tus qauv tsim tau txhim kho los ntawm kev txau thiab sib dhos, lossis galvanized ntawv vuam, lossis electrophoresis thiab txau tom qab vuam.

(6) Cov qauv vuam yuav tsum zam cov qhov nqaim thiab qhov chaw nqaim uas cov phom tsuag tsis tuaj yeem nkag mus.

(7) Cov qhov cua sov yuav tsum tau tsim los ua cov khoom kom deb li deb tau kom tsis txhob muaj cov welds nqaim thiab cov txheej sib txuas.

(8) Lub pas nrig xauv thiab lub pob khawm uas yuav yuav tsum tau ua los ntawm 304 stainless hlau kom deb li deb tau, thiab lub sijhawm tiv thaiv ntsev tsis muaj zog yuav tsum tsis pub tsawg dua 96h GB 2423.17.

(9) Lub phaj ntawv yog tsau nrog cov rivets tsis muaj dej lossis cov nplaum nplaum, thiab kev kho dej yuav tsum tau ua thaum nws xav tau kev txhim kho nrog cov ntsia hlau.

(10) Kev xaiv cov fasteners yuav tsum tau kho nrog zinc-nickel alloy plating lossis 304 stainless hlau, zinc-nickel alloy fasteners ua tau raws li qhov kev sim ntsev tsuag tsis muaj xeb dawb rau 96 teev, thiab txhua qhov fasteners raug tsim los ntawm 304 stainless hlau.

(11) Cov khoom siv sib txuas Zinc-nickel yuav tsum tsis txhob siv ua ke nrog cov hlau tsis xeb.

(12) Lub qhov rau kev teeb tsa ntawmchaw them hluav taws xob hauv tsheb evyuav tsum tau ua tiav ua ntej, thiab lub qhov yuav tsum tsis txhob raug tho tom qab muab lub pawg them hluav taws tso rau hauv. Lub qhov nkag ntawm qab ntawm lub pawg them hluav taws yuav tsum tau kaw nrog cov av nkos uas tiv taus hluav taws kom tiv thaiv cov dej noo ntawm qhov chaw nkag mus rau hauv lub pawg los ntawm lub qhov nkag. Tom qab kev teeb tsa, cov khoom siv silicone sealant tuaj yeem siv rau ntawm lub pawg thiab lub rooj teeb tsa cement kom txhawb nqa kev sib khi ntawm hauv qab ntawm pawg.

Tom qab nyeem cov kev cai saum toj no thiab kev tsim qauv tiv thaiv xeb ntawm lub plhaub hlau them lub thawv, tam sim no koj puas paub vim li cas tus nqi ntawm lub thawv them nrog tib lub zog them yuav txawv heev?

Lub sijhawm tshaj tawm: Lub Xya Hli-04-2025